Constrained Demand Translation Engine

Constrained Demand Translation (CDT) accepts the original demand for the finished goods, constraints on the raw material supply, and through analyzing the BOM and linear programming, determine the number of finished goods that may be produced. The CDT engine also supports Production Capacity while computing production plan for finished good items.The end result is an accurate amount that may be promised to meet the demand.

The engine can run in two different modes: Unconstrained Supply Mode, and Constrained Supply Mode. In the Unconstrained Supply Mode, the engine assumes that there are no co-constraints on raw materials. The engine first translates the finished good demand and generates raw material requirements by expanding the bill of materials. The engine also nets the requirements against inventory and supply to generate raw material bucketized order forecasts. Outside the engine, the generated raw material bucketized order forecast can be used to collaborate with the supplier to get promises from the supplier.

Constrained Supply Mode assumes constraints on raw materials. The results of CDT will essentially change the requested amount by lowering some of the requested finished goods.

Tip

For example, if a finished good A requires B and C, and you have demand for 10 As but only have supplier promise for 5 Bs and 6 Cs, then the request for B and C are reduced to 5. This also means that only 5 As can be built, so only 5 are promised.

To run the Constrained Demand Translation Engine:

Log in to the system using a Production Manager role type.

From the Demand Translation menu, select Constrained Demand Translation Engine.

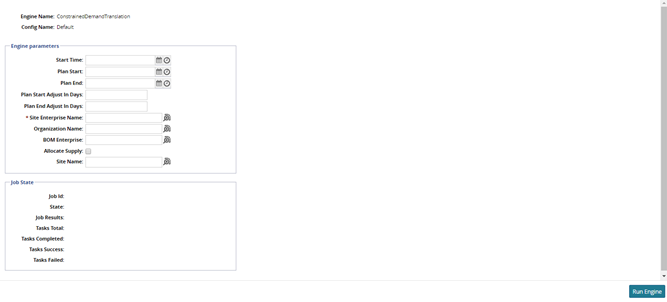

The Constrained Demand Translation Engine screen appears.

Using the picker tool, select a Site Enterprise Name (required).

Select a date and time for Start Time, Plan Start, and Plan End.

Optionally, select values for Plan Start Adjust In Days, Plan End Adjust In Days, Organization Name, BOM Enterprise, Allocate Supply, or Site Name.

To run the engine, click the Run Engine button at the bottom of the page.

A success message appears.To view the status of the engine, click the Job Id link under the Job State heading at the lower portion of the page.

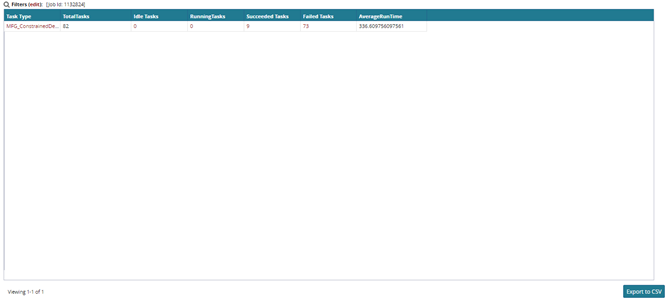

The Job Id page appears.

To view a list of Idle, Running, Succeeded, or Failed tasks, click the number link under the appropriate heading.

A list of tasks appears.To export the list as a spreadsheet, click the Export to CSV button at the bottom of the page.