Creating CDT Agent Configurations

Users can configure basic engine parameters via policies set for the Constrained Demand Translation (CDT) Engine.

When the CDT Engine runs, any configuration overrides default engine parameters or the Intelligent Execution Management (IXM) Engine configuration.

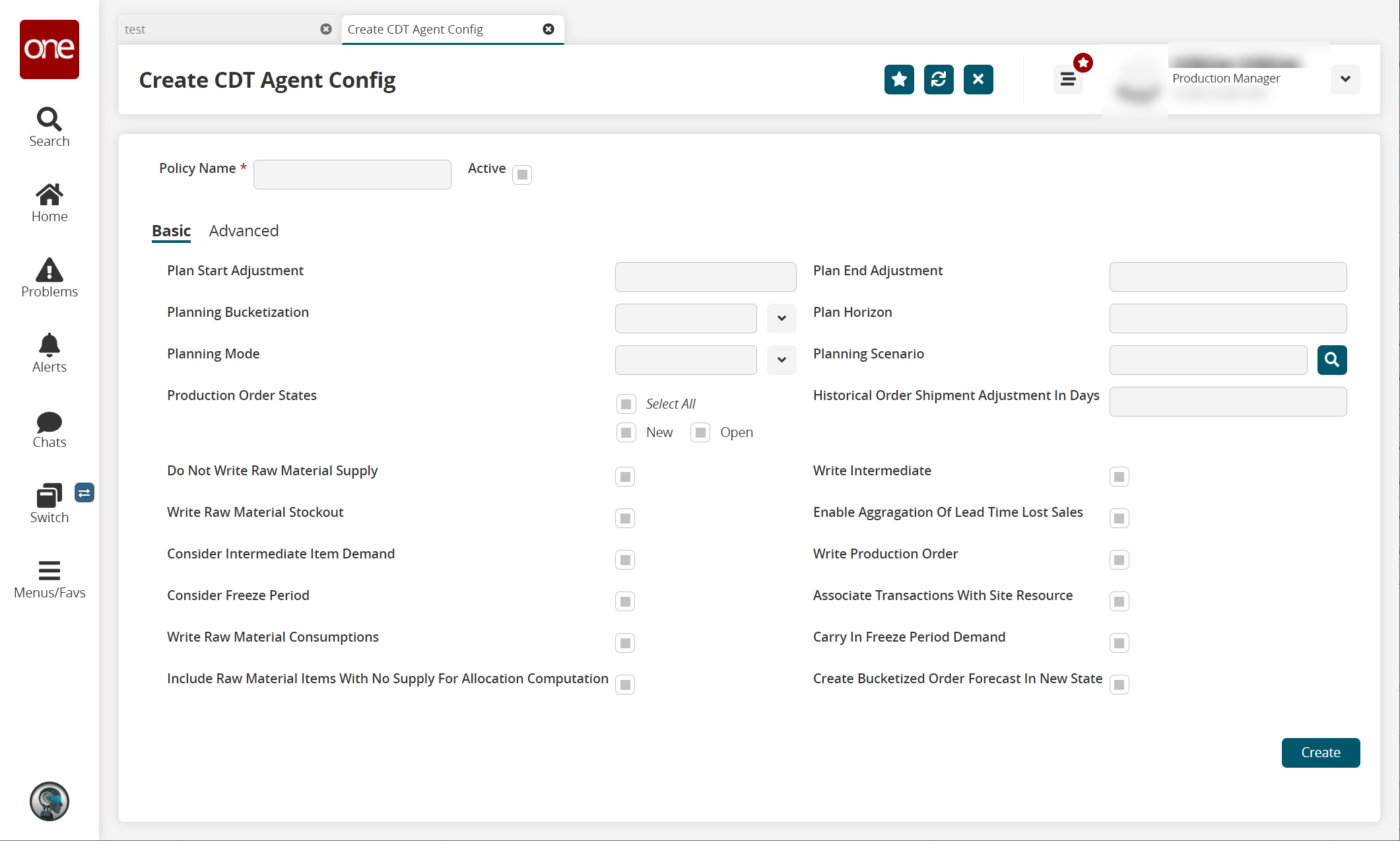

Complete the following steps to create a new CDT agent config:

Log in to the ONE system. Not all users and roles have access to this particular feature.

Click Menus/Favs > Manufacturing Policies > Create CDT Agent Config.

The Create CDT Agent Config screen displays the Basic tab by default.

Enter values for the following fields. Fields with an asterisk ( * ) are required.

Field

Description

* Policy Name

Enter a unique name for the new policy.

Plan Start Adjustment

Planning Bucketization

Select a time bucket from the dropdown list.

Planning Mode

Select a planning mode from the dropdown list.

Production Order States

Enter the production order states as a filter for the engine run.

Do Not Write RM Supply

Check the box if you do not want to write raw material (RM) supply in the engine run.

Write Raw Material Stockout

Check the box if you wish to write raw material stockouts during the engine run.

Consider Intermediate Item Demand

Check the box if you wish the run to include intermediate item demands.

Consider Freeze Period

Check the box if you wish the run to include any freeze period.

Write Raw Material Consumptions

Check the box if you wish the run to write any raw materials consumed.

Include Raw Material Items With No Supply For Allocation Consumption

Check the box if you wish you include any raw materials that have no supply for allocation consumption in the engine run.

Plan End Adjustment

Enter a numerical value for the end adjustment of this plan.

Plan Horizon

Enter a numerical value for the plan's horizon.

Planning Scenario

Use the picker tool to search and select a planning scenario.

Historical Order Shipment Adjustment In Days

Enter the number of days to consider historical order shipment adjustments.

Write Intermediate

Check the box if you wish to write intermediate

Enable Aggregation Of Lead Time Lost Sales

Check the box if you wish to enable the aggregation of lead time for lost sales during the run.

Write Production Order

Check the box if you wish the run to write to the production order.

Associate Transactions With Site Source

Check the box if you wish the run to associate transactions with a site source.

Carry In Freeze Period Demand

Check the box if you wish the run to consider the carry-in freeze period demand.

Click the Advanced tab to enter values for the following fields:

Field

Description

Finished Goods Item Comparator

Select a value from the dropdown list as a comparison.

Maximum Hill Size

Enter a numerical value for the maximum hill size.

Relative MIP Gap Tolerance

Enter a numerical value for the gap tolerance associated with the relative MIP.

Time Limit In Seconds

Enter a numerical value for the time limit in seconds.

Build Ahead Number of Buckets

Enter a numerical value for the number of buckets in the build ahead scenario.

Late Production Discount Rate

Enter a numerical value for the discount rate on late production.

On Time Production Discount Rate

Enter a numerical value for the discount rate for on-time production.

Component Carry In Discount Rate

Enter a numerical value for the discount rate for any carry in components.

Round Down Factor

Enter a value as a factor to round down to.

Is Just In Time

Check the box if the run includes Just In Time items.

Solver Type

Select a solver type from the dropdown list.

Absolute MIP Gap Tolerance

Enter a numerical value for the gap tolerance of absolute MIP.

Max Bound

Enter a numerical value for the maximum bound.

Promise Shortage Threshold

Enter a numerical value for the threshold of promised shortages.

Fair Share Discount Rate

Enter a numerical value for the fair share discount rate.

Finished Goods Carry In Discount Rate

Enter the discounted rate for carry in finished goods.

Finished Goods Carry Round Down Discount Rate

Disable Fair Share

Check the box if you wish to disable fair share calculations in the engine run.

Recalculate Capacity Consumption

Check the box if you wish to have a recalculation of capacity consumption made in the engine run.

Bucket Transform Function Name

Select a value from the dropdown list.

Click the Create button.