Order Aggregation Engines

For order aggregation, the Load Builder reads orders and order forecasts and combines them in a manner to maximize load efficiency. The exact procedure order aggregation follows is determined by set policies. The policies are defined in the IXM engine parameters, and by default, the procedure followed is the Simple Aggregation strategy.

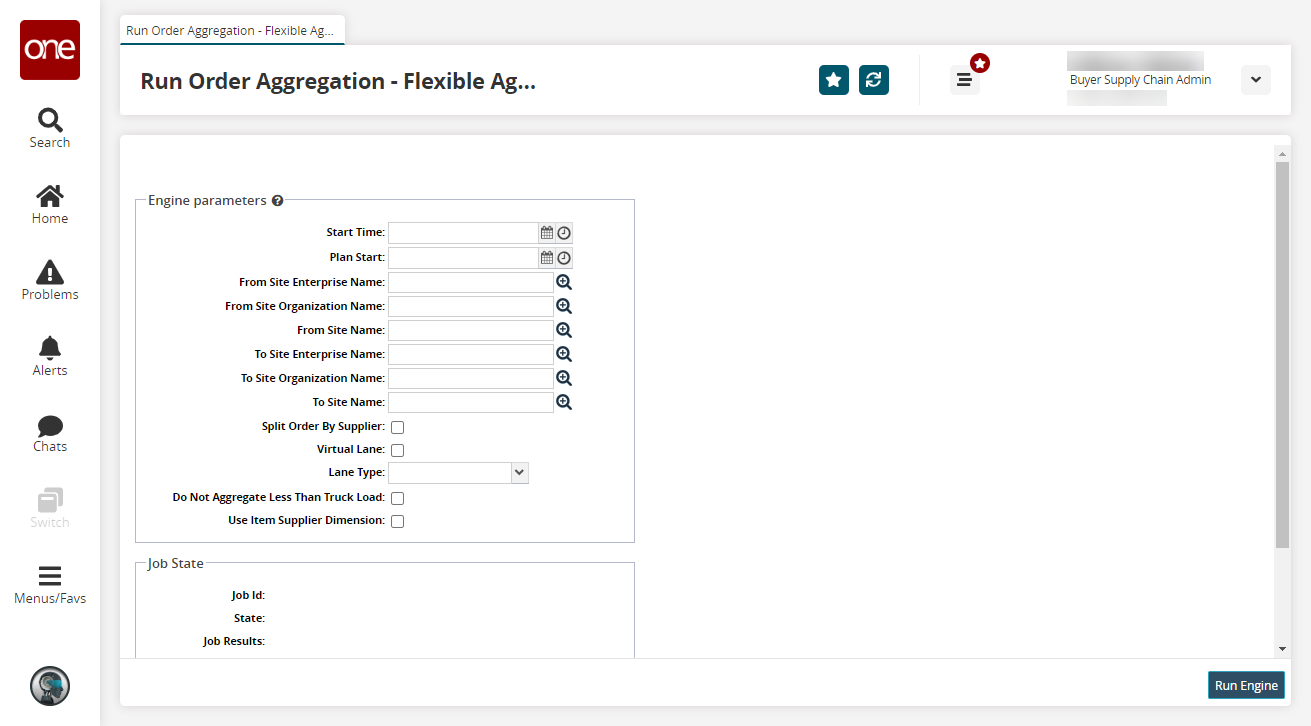

Running the Flexible Aggregation Engine

Users can run the Flexible Aggregation Engine in the One Network system. Flexible allocation is based on the Simple Aggregation strategy. It uses a must-ship and pulls on the horizon to determine the orders and order forecasts it may work with.

Complete the following steps to run the Flexible Aggregation Engine:

L og in to the ONE system.

Click Menus/Favs > Replenishment > Order Aggregation Engine > Run Order Aggregation - FlexibleAggregation. In the NEO UI, users can click on the Menus/Favs icon on the left sidebar and type in the name of the screen in the menu search bar. For more information, see "Using the Menu Search Bar."

The Run Order Aggregation - Flexible Aggregation screen displays.

Enter values for fields described in the table below. Fields with an asterisk ( * ) are required.

Field

Description

Start Time

Use the calendar and clock tools to set the start time.

Plan Start

Use the calendar and clock tools to set the plan start.

From Site Enterprise Name

Enter or use the picker tool to select the from-site's enterprise name.

From Site Organization Name

Enter or use the picker tool to select the from-site's organization name.

From Site Name

Enter or use the picker tool to select the from-site's name.

To Site Enterprise Name

Enter or use the picker tool to select the to-site's enterprise name.

To Site Organization Name

Enter or use the picker tool to select the to-site's organization name.

To Site Name

Enter or use the picker tool to select the to-site's name.

Split Order By Supplier

Check the box to split the order by supplier in the run.

Virtual Lane

Check the box to set this run for a virtual lane.

Lane Type

Select a lane type from the dropdown menu.

Do Not Aggregate Less Than Truckload

Select this checkbox to prevent aggregation when there is less than a truckload.

Use Item Supplier Dimension

Select this checkbox to use item supplier dimensions instead of item dimensions. This can be useful when, f or example, an item may weigh one pound sourced from vendor site 1, but due to packa ging differences, the same item may weigh two pounds when sourced from vendor site 2.

If not enabled, the system behaves as it did before this update, using item dimensions as expected.

Click the Run Engine button.

A success message indicates that the engine is scheduled.

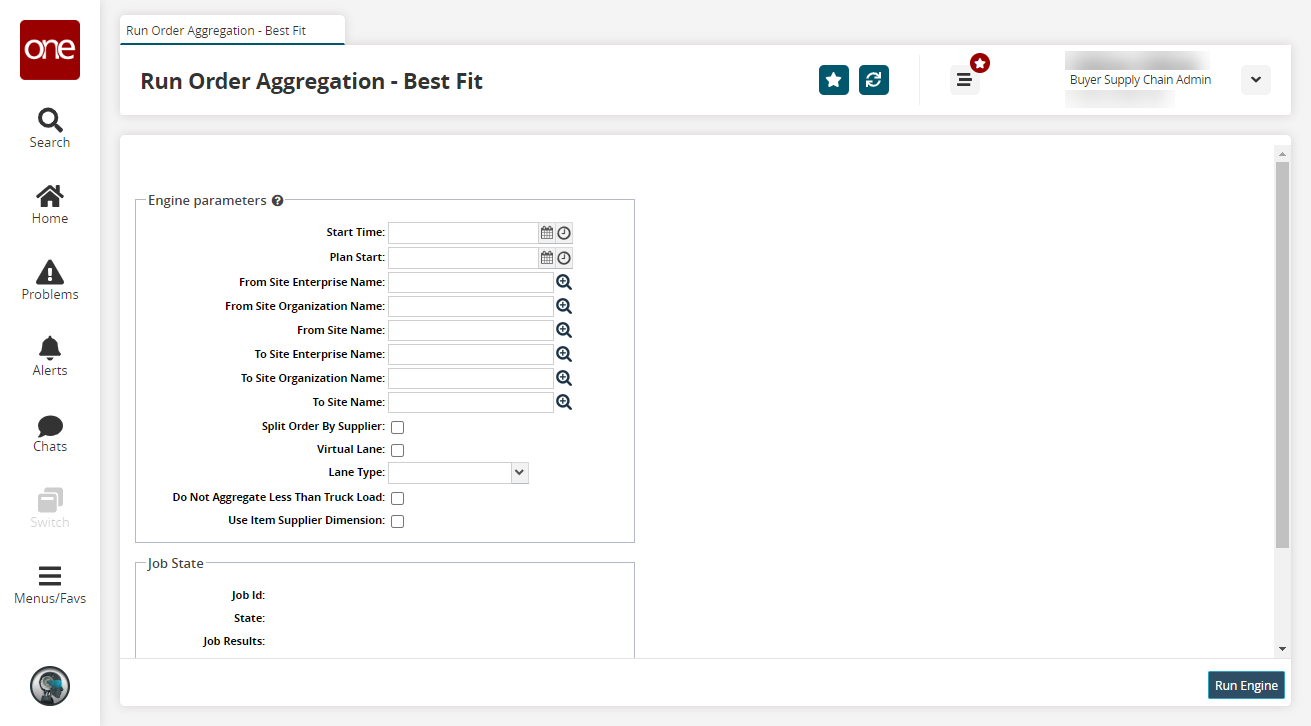

Run the Best Fit Engine

Users can run the Best Fit Engine to generate a load that maximizes product for the available equipment space.

Order Aggregation has policies for creating orders and forecasts that fill the smallest equipment first to reduce the price of shipping. Sometimes, due to equipment rules, order forecasts are partially split to accommodate such rules.

Complete the following steps to run the Best Fit Engine:

Click Menus/Favs > Replenishment > Order Aggregation Engine > Run Order Aggregation - Best Fit.

The Run Order Aggregation - Best Fit screen opens.

Enter values for fields described in the table below. Fields with an asterisk ( * ) are required.

Field

Description

Start Time

Use the calendar and clock tools to set the start time.

Plan Start

Use the calendar and clock tools to set the plan start.

From Site Enterprise Name

Enter or use the picker tool to select the from-site's enterprise name.

From Site Organization Name

Enter or use the picker tool to select the from-site's organization name.

From Site Name

Enter or use the picker tool to select the from-site's name.

To Site Enterprise Name

Enter or use the picker tool to select the to-site's enterprise name.

To Site Organization Name

Enter or use the picker tool to select the to-site's organization name.

To Site Name

Enter or use the picker tool to select the to-site's name.

Split Order By Supplier

Check the box to split the order by supplier in the run.

Virtual Lane

Check the box to set this run for a virtual lane.

Lane Type

Select a lane type from the dropdown menu.

Do Not Aggregate Less Than Truckload

Select this checkbox to prevent aggregation when there is less than a truckload.

Use Item Supplier Dimension

Select this checkbox to use item supplier dimensions instead of item dimensions. This can be useful when, f or example, an item may weigh one pound sourced from vendor site 1, but due to packa ging differences, the same item may weigh two pounds when sourced from vendor site 2.

If not enabled, the system behaves as it did before this update, using item dimensions as expected.

Click the Run Engine button.

A success message indicates that the engine is scheduled.

Tip

To refresh the engine status, click the Refresh button.