Run (Invoke) Inventory Planning Engine

Complete the following steps to run the Inventory Planning Engine:

Log in to the ONE system.

Click Menus/Favs > Inventory Planning > IP Engine > Invoke Inventory Planning Engine.

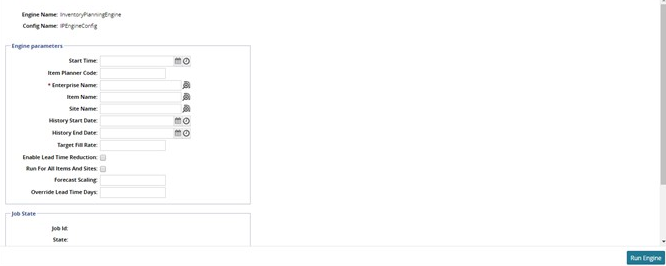

The Invoke Inventory Planning Engine screen opens.

Enter the required information in the Engine Parameters section. Fields with an asterisk are required.

Field

Description

Start Time

The start time for the engine. As a default, if a start time is not selected, the engine runs immediately.

Item Planner Code

Limit items to those linked to a specific item code.

Enterprise Name

Click the picker tool icon to select an enterprise.

Item Name

Click the picker tool icon to select an item. If no item is selected, all items are included in the engine run.

History Start Date

The start date of the time period that historical data, like demand history and forecast history, are to be considered. If no date is selected, the system uses either Site Supplier or the Buffer Lane settings.

History End Date

The end date of the period that historical data, like demand history and forecast history, are to be considered. If no date is selected, the system uses either Site Supplier or the Buffer Lane settings.

Target Fill Date

The desired fill rate or service level to be achieved. Influences the statistical safety stock, the min, and the simulated safety stock for both dynamic and static policies.

Enable Lead Time Reduction

Lead Time Reduction is a feature of the Safety Stock Simulations. Allows for shorter lead time transportation modes to be taken to improve service levels. Essentially allows the system to increase transportation costs to allow smaller Safety Stock levels.

Run For All Items and Sites

If selected, run the engine for all items and sites.

Forecast Scaling

Scale up or down a forecast based on a user's expectation of what the forecast will be in the future rather than the current forecast data.

Override Lead Time Days

Similar to Enable Lead Time Reduction, except the user enters the actual lead time. Allows users to experiment with different lead times to show how it impacts Safety Stock.

Click the Run Engine button at the bottom of the page.

A success message appears.