Run Demand Planning

The Demand Planning (DP) Forecast Generation engine is a long-term statistical forecasting engine, which produces forecasts based on existing demand history data (for example, point-of-sale or shipments). The DP engine relies upon advanced statistical forecasting techniques to support sales seasonality and promotional events (for example, advertising or price reductions).

Complete the following steps to run the Demand Planning engine:

Log in to the ONE system.

Click Menus/Favs > Demand Planning > Forecast Processing > Run Demand Planning.

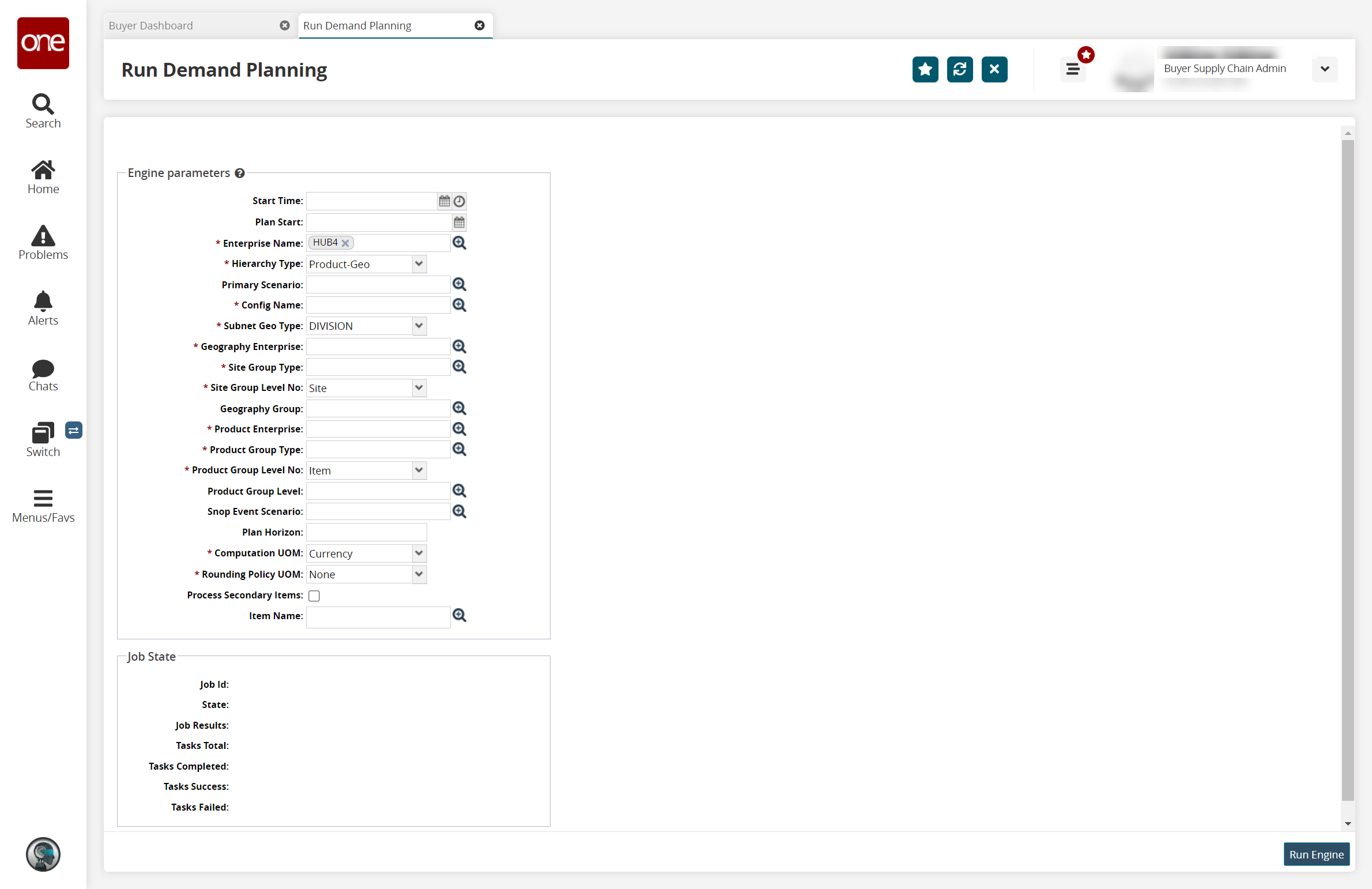

The Run Demand Planning screen displays.

Using the table below, fill in the required fields and any additional parameters you require. Fields with an asterisk ( * ) are required.

Field Name

Description

Start Time

Click the calendar icon to select a specific date and time when the engine should begin.

Plan Start

Click the calendar icon to select the start date and time of the demand plan.

*Enterprise Name

Click the picker tool icon to select the name of the Enterprise for which the engine runs.

*Hierarchy Type

Select the hierarchy type from the dropdown list. This type defines the set of input parameters for the split ratio.

Primary Scenario

Click the picker tool icon to select the primary scenario. If this field is set, the DP engine plans for an SNOP "what-if" scenario and writes results to the appropriate S&OP-specific data models. If this field is left blank, a normal execution plan is generated.

*Config Name

Click the picker tool icon to select the demand planning scenario name.

*Subnet Geo-Type

Choose either "DC" or "Division." If set to "DC," then the assumption is that each Site Group Level maps to the distribution center (DC) site.

*Geography Enterprise

Click the picker tool icon to select the name of the site group enterprise for which the engine runs.

*Site Group Type

Click the picker tool icon to select the site group type, such as Supply Hierarchy.

*Site Group Level No

Select the site group level number from the dropdown list.

Geography Group

Click the picker tool icon to select the geography group.

*Product Enterprise

Click the picker tool icon to select the name of the Product Group Enterprise for which the engine runs.

*Product Group Type

Click the picker tool icon to select the Product Group Type.

*Product Group Level No

Select the product group level number from the dropdown list.

Product Group Level

Click the picker tool icon to select the supported level of the Product Hierarchy.

SNOP Event Scenario

If this field is set, the DP engine will plan for the according SNOP "what-if" scenario and read events for this scenario. If this field is not set, the DP engine will fall back to read regular events.

Plan Horizon

Overrides weekly horizons set by the Demand Planning Scenario.

*Computation UOM

Select the computation unit of measurement (UOM) from the dropdown list.

*Rounding Policy UOM

Setting to Unit or Currency tells the system to round to the nearest whole integer. This policy should be enabled for slow-moving products.

Process Secondary Items

Select the checkbox to tell the system to process secondary items during the engine run.

Item Name

Click the picker tool icon to select the item name.

Once all information has been entered, click the Run Engine button.

A success message appears.To check the status of the engine, click the Job ID # link in the Job State section.