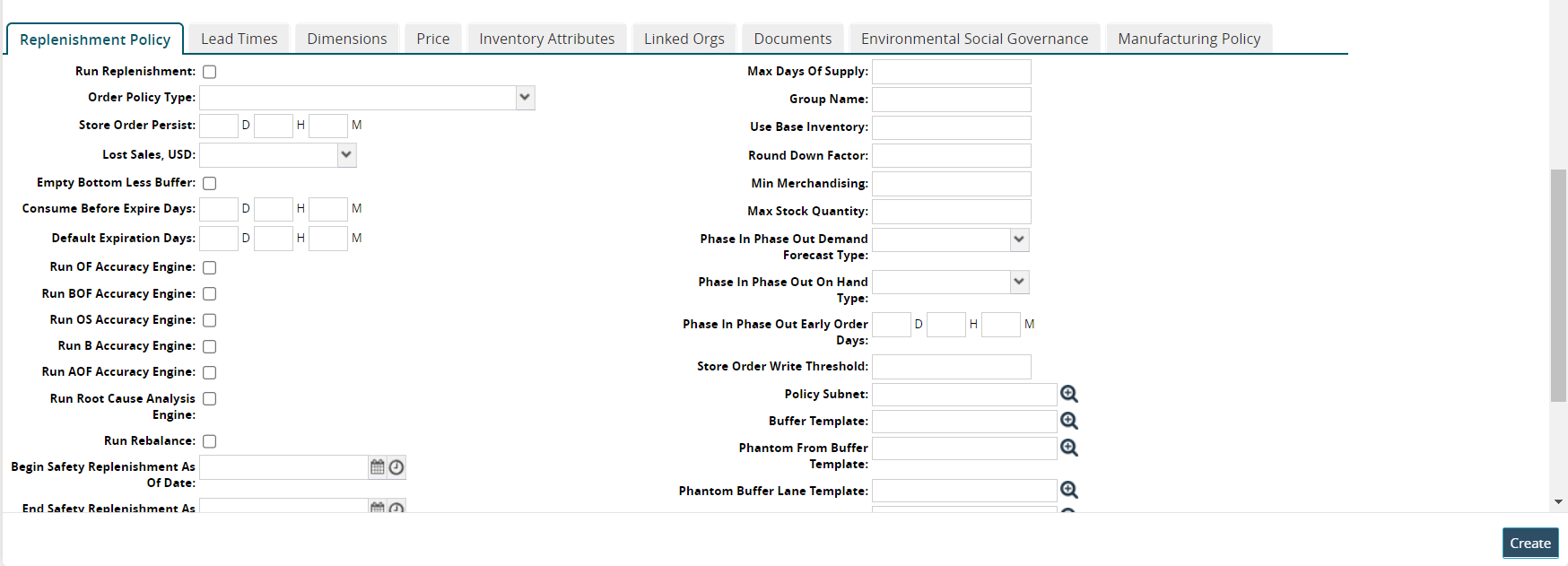

Replenishment Policy Tab for Buffers

You can set a replenishment policy for each new buffer you create.

Complete the following steps to set the replenishment policy:

From the New Buffers page, click the Replenishment Policy tab.

There are two sets of fields you will define for the replenishment policy tab. The first column, on the left, is determined by the value selected for Order Policy Type. The second column, on the right, stays constant for all of the order policy types.

Enter values for the fields described below. The fields on the left display when null is selected for the Order Policy type field; the fields in the right column are consistent for all order policy types. The left column fields will differ according to the order policy type.

Field

Description

Run Replenishment

Check the box to run the Replenishment engine.

Order Policy Type

Select the order type policy using the dropdown list. Depending on the type option selected, additional fields appear.

Store Order Persist

Enter numerical values for days, hours, and minutes.

Lost Sales, USD

Select a value from the dropdown list to add lost sales into the calculation.

Empty Bottom Less Buffer

Check the box to create an empty bottomless buffer.

Consume Before Expire Days

Enter numerical values for days, hours, and minutes.

Default Expiration Days

Enter numerical values for days, hours, and minutes.

Run OF Accuracy Engine

Check the box to include this buffer when running the order forecast accuracy engine.

Run BOF Accuracy Engine

Check the box to include this buffer when running the bucketized order forecast accuracy engine.

Run OS Accuracy Engine

Check the box to run this accuracy engine.

Run B Accuracy Engine

Check the box to run this accuracy engine.

Run AOF Accuracy Engine

Check the box to run this accuracy engine.

Run Root Cause Analysis Engine

Check the box to run a root cause analysis.

Run Rebalance

Check the box to run a rebalance calculation.

Begin Safety Replenishment As Of Date

Use the calendar and clock icons to set the date for when safety replenishment should begin.

End Safety Replenishment As Of Date

Use the calendar and clock icons to set the date for when safety replenishment should end.

Forecast Consumption Type

Select the consumption type for this forecast from the dropdown list.

Exclude Sales Order In Forecast Consumption

Check the box to exclude sales orders when calculating the forecast consumption.

Exclude Purchase Order In Forecast Consumption

Check the box to exclude purchase orders when calculating the forecast consumption.

Exclude Deployment Order In Forecast Consumption

Check the box to exclude deployment orders when calculating the forecast consumption.

Exclude Store Order In Forecast Consumption

Check the box to exclude store orders when calculating the forecast consumption.

Max Days Of Supply

This value represents the maximum DOS (Days of Supply) that must not be exceeded when rounding order quantity up due to lot size.

Group Name

Subdivision of the network in which to run the engines such as Load Builder, Advanced Replenishment, Standard Replenishment, and Retail Replenishment.

Apply Forecast Netting

Forecast netting is the comparison of Demand Forecast and Outbound Orders. If turned on, the maximum of Demand Forecast or Outbound Orders acts as demand for that day. If turned off, then the demand for that day is the sum.

Use Base Inventory

Use your base inventory for the buffer policy.

Round Down Factor

Enter a numerical value for rounding down. The round down factor describes to what percentage of the minimum or incremental lot size the quantity is rounded down.

Min Merchandising

Enter a numerical value for a flat minimum quantity required for the buffer. This can be used in conjunction with safety stock. The Min Merchandising can be used to set a floor value as demand decreases, so the store shelf does not look empty.

Max Stock Quantity

Enter a numerical value for the maximum stock quantity.

Phase In Phase Out Demand Forecast Type

Select the demand forecast type from the dropdown list. If the phase-in and phase-out functionality is enabled, it dictates how the engine handles demand forecast during the transition from an older item to a newer item.

Phase In Phase Out On Hand Type

Select the onhand type from the dropdown list.

Phase In Phase Out Early Order Days

Enter the (D)ays, (H)ours, (M)inutes establishing how early we can order the new item.

Store Order Write Threshold

Enter a numerical value for the threshold for store order writing.

Policy Subnet

Use the picker tool to select a policy subnet to identify the buffer as a member of a group of replenishment policies.

Buffer Template

Use the picker tool to link the buffer to a template. If linked to a template, then changes may be made to the template and copied to all buffers linked to that template.

Phantom From Buffer Template

Use the picker tool to select a template. If the Phantom Network feature is turned on, it defines the template to be used instead of the From Buffer.

Phantom Buffer Lane Template

Use the picker tool to select a template. If the Phantom Network feature is turned on, it defines the template to take the place of the buffer lane.

Phantom Site Lane Template

Use the picker tool to select a template. If the Phantom Network feature is turned on, it defines the template to take the place of the site lane.

Rounding Type

Select a rounding type from the dropdown list. The rounding type allows you to define multiple lot sizes for a given item; however, a combination of lot sizes is not supported. If you select the Multiple option, you can enter up to four values of lot sizes, and during the replenishment engine run, those values will be taken into consideration rather than minimum, maximum, and incremental lot size values.

Alt 1 Inclot Size Quantity

Enter an alternate "including overtime" numerical value for the size quantity.

Alt 2 Inclot Size Quantity

Enter an alternate "including overtime" numerical value for the size quantity.

Alt 3 Inclot Size Quantity

Enter an alternate "including overtime" numerical value for the size quantity.

Alt 4 Inclot Size Quantity

Enter an alternate "including overtime" numerical value for the size quantity.